The Essential Guide to Choosing the Right Industrial Scales for Your Needs

The Essential Guide to Choosing the Right Industrial Scales for Your Needs

Blog Article

Why to Select Industrial Scales for Accurate Weight Dimension in Different Industries

In an era where precision is extremely important, the selection of industrial ranges for accurate weight measurement plays a vital duty across diverse markets. These ranges not just enhance operational effectiveness yet additionally guarantee compliance with regulative criteria, affecting whatever from manufacturing to shipping.

Importance of Accurate Weight Measurement

In the realm of industrial operations, the significance of precise weight dimension can not be overstated. Precise weight measurement is foundational across different industries, influencing both operational efficiency and item top quality - Industrial Scales. It acts as a crucial factor in supply administration, guaranteeing that products are adequately accounted for, consequently minimizing waste and lowering prices

In production, exact weight measurement straight impacts production procedures. Anomalies in weight can bring about low-grade items or too much source allowance, impacting general profitability. In addition, in industries such as pharmaceuticals and food manufacturing, adherence to rigorous weight specs is vital for regulative compliance and customer security.

Furthermore, accurate weight dimensions help with effective logistics and supply chain monitoring. Properly considered deliveries ensure that transportation expenses are optimized which stock levels are kept precisely, thereby protecting against stock scarcities or overstock situations.

Sorts Of Industrial Scales

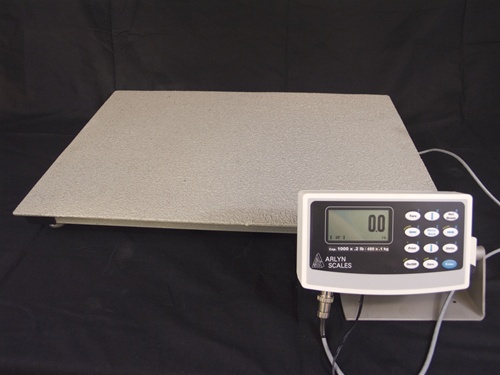

A wide range of commercial scales are readily available, each developed to meet certain dimension needs across varied industries. Usual kinds include flooring scales, which are suitable and durable for weighing big items or pallets in warehouses and circulation facilities. Bench ranges are smaller and optimal for lighter products, frequently made use of in retail settings or making for specific portion control.

An additional category is portable ranges, which provide the versatility to be relocated conveniently around work websites, making them perfect for field procedures or short-lived configurations. Precision scales, on the various other hand, are designed for high accuracy and are often used in labs and quality control settings.

Load cells are essential elements in different commercial ranges, transforming pressure into an electric signal for precise analyses. In addition, vehicle ranges provide the means to consider heavy automobiles and their loads, making certain compliance with regulations and optimizing logistics.

Last but not least, checkweighers immediately compare the weight of items versus pre-programmed restrictions, enhancing quality control in assembly line (Industrial Scales). Each type of commercial range offers a special function, catering to the specific needs of sectors such as production, logistics, food processing, and drugs

Advantages of Utilizing Industrial Scales

Constantly using industrial ranges offers significant advantages throughout numerous markets. One of the primary advantages is boosted precision in weight measurement, which is important for maintaining top quality criteria and regulative compliance. Exact dimensions avoid costly mistakes in production, delivery, and supply administration, check my site eventually resulting in increased operational efficiency.

Moreover, commercial scales are created for longevity and effectiveness, enabling them to hold up against rough environments commonly discovered in manufacturing and warehousing. This strength ensures a lengthy lifespan, decreasing the requirement for regular replacements and upkeep expenses.

In addition, using industrial ranges boosts safety and security and minimizes waste. By guaranteeing that products are weighed accurately, companies can stay clear of straining explanation cars, which can cause penalties and crashes.

Applications Across Different Industries

Industrial scales play a crucial function in numerous sectors, consisting of production, logistics, food handling, and pharmaceuticals. In production, these ranges are vital for making certain that resources are determined precisely, thus maintaining item high quality and uniformity (Industrial Scales). Precision in weight dimension straight impacts production efficiency and price administration

In logistics, industrial ranges promote the precise evaluating of deliveries, which is essential for adhering to optimizing and delivering guidelines freight prices. Precise weight data aids simplify procedures and enhances supply chain monitoring.

The food handling sector depends greatly on industrial scales for compliance with wellness and security regulations. They are made use of to weigh active ingredients specifically, ensuring that formulas satisfy both quality requirements and legal demands. This is essential not only for consumer security but additionally for maintaining brand name integrity.

Drug firms utilize industrial scales to make sure exact dosages in medication manufacturing, where even the tiniest deviation can have substantial consequences. Conformity with rigorous regulatory standards makes exact weight dimension important in this market.

## Factors to Think About When Selecting Ranges

Choosing the right range for certain applications requires cautious consideration of several elements. Primarily, the ability of the range is essential; it needs to fit the optimum weight of the things being gauged without surpassing its restrictions. Furthermore, the readability, or smallest increment the scale can properly show, is important for precision, specifically in markets where weight discrepancies can bring about substantial economic losses read the full info here or safety and security problems.

Ecological conditions also play a significant role in scale choice. Scales made use of in moist or destructive atmospheres may call for specific products to make sure resilience. Likewise, portability might be important in specific applications, necessitating battery-operated and lightweight designs.

Conclusion

In final thought, the option of industrial ranges is essential for guaranteeing accurate weight measurement throughout varied sectors. Therefore, spending in high-quality industrial scales is crucial for organizations aiming to preserve high criteria and optimize productivity.

Report this page